In the sun-drenched, bustling province of Khon Kaen, a tale unfolded that could easily be mistaken for a high-octane movie plot. At the heart of the drama was Ratchaphon Khiannok, a 35-year-old with a dubious distinction on his resume—convicted drug offender. Alongside his spry 20-year-old sidekick, Palangwatchara Khunsinchairat, Ratchaphon’s latest escapade came to a crashing halt at a seemingly peaceful resort, painting a picture of crime and desperation that few fiction writers could conjure. Our saga begins with Ratchaphon, freshly slapped with a verdict on drug charges, making a daring daylight escape from the clutches of the law. With the sort of audacity that leaves onlookers agape, he shimmied over the court’s fence, fetters clanking with every movement, to a getaway motorcycle manned by none other than his loyal accomplice, Palangwatchara. The duo’s flight from justice led them to the comforting confines of a relative’s home where they sought refuge…

THAI.NEWS - Thailand Breaking News

In an emotionally charged scene reminiscent of a stand against historical injustices, families, their hearts heavy with years of grief and eyes ablaze with a demand for justice, stood outside the Narathiwat Provincial Court. Their banners, more than mere pieces of fabric, were powerful symbols of the enduring quest for justice regarding the harrowing Tak Bai massacre. This tableau unfolded in the south of Thailand, a region whose beauty and tranquility belie a history of turmoil and suffering, particularly that cold day in October 2004 which has etched itself indelibly into the collective memory of the people of Tak Bai. Thursday brought an air of grim determination as injured protestors and grieving families, still haunted by the specter of that fateful day’s tragedy, took a monumental step. They brought forth a lawsuit against nine individuals who once stood at the zenith of power in southern Thailand. These former officials, accused…

In the heart of Narathiwat province, an emotional gathering unfolds outside the Provincial Court in Muang district. It’s a scene painted with hope and determination, as families clutch banners high into the sky, their faces a mix of strength and sorrow. They’re here to demand justice for a wound etched deep into their collective memory—the Tak Bai massacre. Their banners, a silent yet powerful testament to their unwavering resolve, flutter as guardians of their plea for retribution. The courthouse, on this pivotal Thursday, becomes a battlefield without weapons, where injured protesters and the bereaved families of Tak Bai’s darkest day step into a new kind of fight. This time, their arsenal comprises legal documents, their targets: nine former top officials whose decisions led to a tragedy that has marred the soul of a community. Represented by a battalion of human rights lawyers, these 48 plaintiffs embark on a path rarely…

Imagine the colorful markets of Thailand, bustling with innovation, colliding with the dynamic financial landscape of Australia. This week, a scene that could be straight out of a fintech fairy tale unfolded as Thailand and Australia decided to join forces, signing a pact that promises to propel the local fintech scene into a realm of unforeseen growth and collaboration. The memorandum of understanding (MoU), a beacon of future prosperity, was meticulously penned by the Thai Fintech Association and FinTech Australia. Brian Collins, the esteemed Deputy Chair of FinTech Australia, couldn’t hide his excitement as he talked about the fertile ground Southeast Asia, and particularly Thailand, offers for the thriving Australian fintech sector. “Thailand and Southeast Asia are not just coordinates on a map, but a treasure trove of opportunity for our local fintech mavens. It’s a region our members are keenly interested in, largely due to its speedy embrace of…

In the ever-dynamic and bustling world of Thai politics, a seismic shift appears to be on the horizon, heralded by none other than the venerable Pichai Chunhavajira. Known for his astute advisory role to Thailand’s Prime Minister Srettha Thavisin, Pichai, at the ripe age of 76, is now poised to take the financial reins of the nation as the next Finance Minister. This strategic play unfolds amid a backdrop of captivating political chess, where the Pheu Thai Party seems set to cede several cabinet positions to their coalition counterparts. Fresh off his resignation from three high-profile roles – the Chairman of the Stock Exchange of Thailand (SET), Bangchak Corp, and BCPG Plc – Pichai’s pivot to political prominence is talk of the town. His decision fuels speculation and excitement, marking the beginning of a new chapter not only for him but for Thai governance at large. The intrigue deepens with…

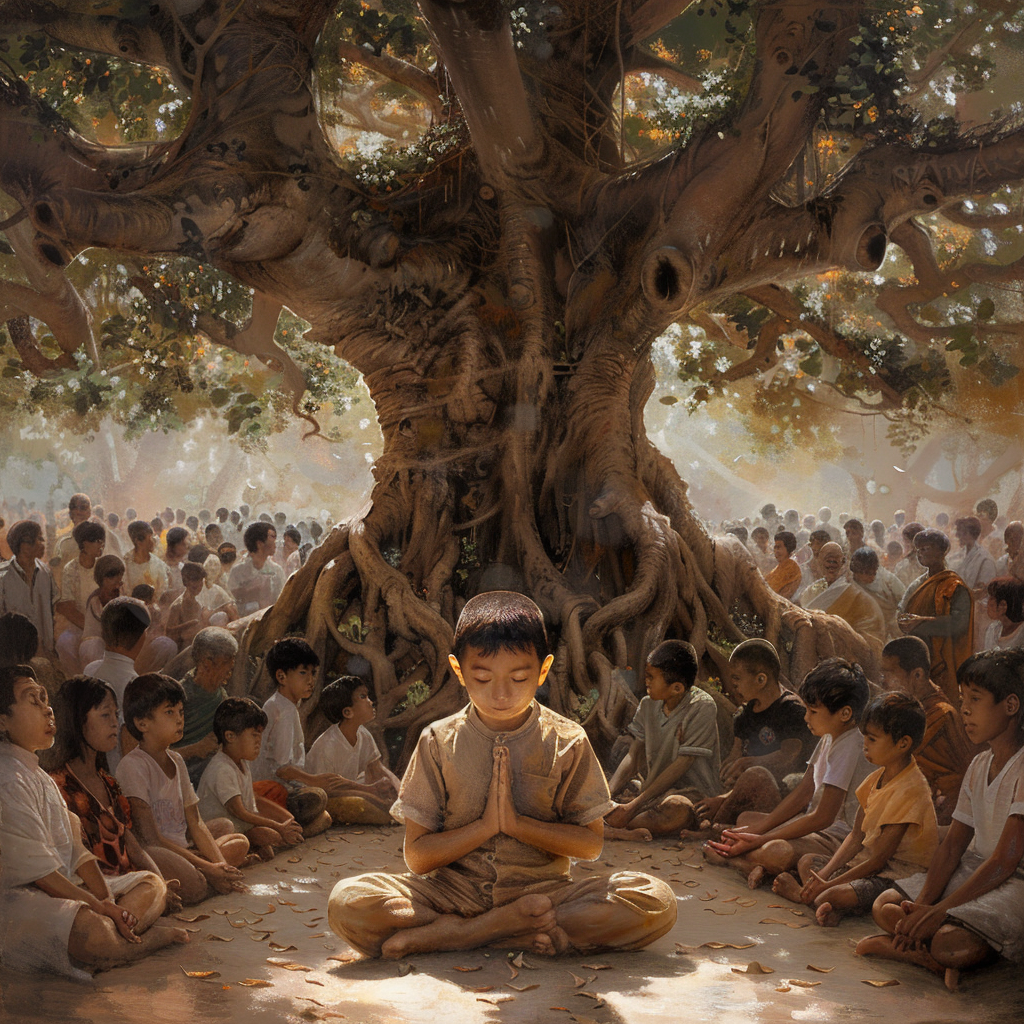

In the heart of Thailand, a story has unfolded that has captured the nation’s interest and stirred a fair share of skepticism and curiosity. The tale centers around an eight-year-old boy, affectionately known as “Nong Nice,” who is no ordinary child. His parents have made a claim heavy with ancient echoes; they assert that Nong Nice is the reincarnation of the Lord Buddha himself. With a narrative this compelling, it’s no surprise that both the faithful and the cynical have turned their attention to this young preacher. The whispers of Nong Nice’s extraordinary abilities began to spread like wildfire. It was said that this child prodigy could connect telepathically with his followers, guiding them through the intricacies of meditation with the wisdom far beyond his years. Courses and forums purportedly led by Nong Nice became the new pilgrimage sites for those seeking enlightenment, drawing crowds eager to bask in the…

Imagine the colossal USS Theodore Roosevelt, a United States Navy aircraft carrier, gracefully navigating through the waters to make its grand entrance at Laem Chabang, Thailand. This isn’t just any visit; it’s a majestic meeting of cultures, a bridge-building mission between two countries with a rich history and shared values. Rear Admiral Christopher Alexander, the mastermind behind Carrier Strike Group Nine, sees this as more than a diplomatic handshake—it’s a chance to weave stronger bonds and showcase the unwavering friendship between the United States and Thailand. According to R Adm Alexander, such visits are part of the carrier’s routine patrols across the Western Pacific. Yet, there’s nothing routine about the excitement and anticipation this brings to the sailors on board. It’s their golden ticket to embracing the vibrant culture of Thailand, to meet its people, and to forge not just alliances, but friendships. After all, the mission is multifaceted: strengthen…

In the heart of Rayong, a tale of fire, chemistry, and heroism unfolds under the shadow of the evening sky. Just this past Wednesday night, the Win Process hazardous waste storage plant found itself once again at the mercy of an untamed blaze. This was no ordinary fire, my friends—this was a conflagration born from the bowels of industrial might, set alight in Ban Nong Pawa village, a tranquil community now thrust into the limelight of peril. The protagonist of our story, Building 3, was not just any structure. It was a treasure trove of aluminium dross, amounting to some 10,000 tonnes of the stuff. Now, for those unacquainted with the fiery temperament of aluminium dross, let me enlighten you. This is no run-of-the-mill refuse. When ignited, it scoffs at the idea of being quenched by water, for such an act only serves to fan its flames, emboldening the fire…

In a bold and decisive move, Prime Minister Srettha Thavisin has sounded the alarm on safety standards in chemical storage across the nation, thrusting us into a narrative that seems straight out of an industrial thriller. With the air still tinged with the remnants of recent calamities, the Prime Minister’s mandate comes as a clarion call to inspect every nook and cranny of the country’s chemical warehouses. This directive was announced with a sense of urgent resolve by the government’s spokesperson, Chai Wacharonke, in a storyline that unfolded amid the smoky backdrop of yet another chemical misadventure. Imagine the quiet of the night shattered by the ominous sight of smoke snaking its way into the sky over Bang Mot neighbourhood in Bangkok’s Chom Thong district. It was here, in the dead of night, that locals were roused not by dreams but by the acrid smell of chemicals besieging their senses.…

Once upon a time, as Labour Day approached, whispers and rumors of a significant change began to swirl through the streets and alleys of Thailand. Workers, with hopeful hearts, awaited an announcement that promised to turn the tide in their favor—a proposed minimum daily wage hike to 400 baht set to begin on the first of May. Alas, like a plot twist in an enthralling novel, the government, starring Deputy Government Spokesman Karom Polpornklang, unveiled an unexpected turn of events. Under the golden rays of the Thai sun, Polpornklang stepped forward, his voice echoing a mixture of resolve and anticipation. He announced that the eagerly awaited wage increase would not unfurl its wings on Labour Day. Instead, like the climax of a gripping drama, the decision’s fate would be postponed until May 14th, when a gathering of minds—a tripartite committee—would deliberate its feasibility. The air buzzed with intrigue as Polpornklang…